The Steel:

|

|

|

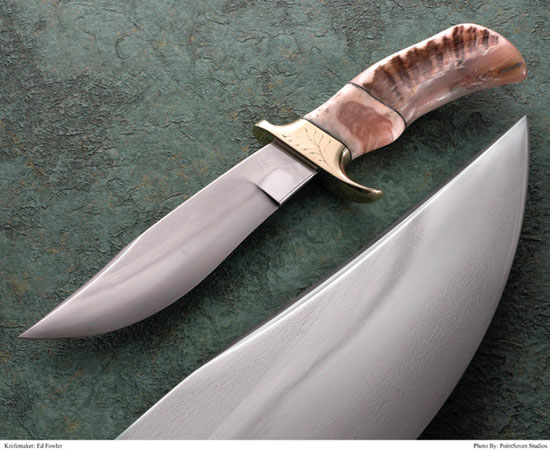

Visible grain structure and transition zone |

My steel of choice is hand forged 52100 steel, the steel of ball bearings. Based upon extensive comparison shop testing and field evaluation I believe that when carefully forged and heat treated, this is the most versatile and dependable steel available to the knife industry.

The knives I make can cut with the best, demonstrate more than adequate strength (difficult to bend), will still flex to 90 degrees without cracking and are easy to sharpen with a simple pocket stone.

I feel that a man who depends on his knife deserves and needs the most reliable knife possible that will not bend easily or break when he needs it the most. A knife that can be sharpened easily and is friendly to his hand.

Forged Blades: Since 1985, I have forged all my blades. Although I had made many knives before that time, some of them forged, I believe that when I dedicated myself to the forged blade, I started on my way to becoming a knife maker. Forging knife blades is more time consuming but forging gives me the freedom to make knives of any steel I choose to use, to work that steel in such a manner as to push it to its absolute limits of performance. I firmly believe that there is NO finer using knife than one blessed with a properly forged, hardened, and tempered blade of a steel the knife maker knows well.

The blades I forge now are the result of a dream I have sought for over 60 years. They are the best I have to offer after searching for our vision of Excalibur since my Grandmother first read the legends of King Arthur to me as a child.

The properties in these blades are much more than one man could have achieved alone, they are a result of the dreams of a team that have worked with me over the past 30 years. When I started there were few books and the internet was unknown to me, I worked alone and progress was slow. One day in 1982 I found a book by Ken Warner, the first DBI Knives Annual edition. I read, I learned, I called some knife makers and learned more. When I read about wire Damascus in a 1986 article written by Wayne Goddard, I called Wayne who shared with me and we decided to conduct some experiments and share what we learned. For a few years the information we gained together seemed to have no end, in those days sharing information meant phone calls and hand written letters, our enthusiasm made it all worthwhile.

The properties developed in the knife I make today have evolved very slowly and are the product of the experience and dreams of many knifemakers, for no one man alone could have developed what we have achieved together. It all started with teachers who encouraged the pursuit of knowledge beyond the classroom, then a class taught by Bill Moran who taught in such a manner as to nurture curiosity for what could be. Many blade smiths have helped me by contributing their knowledge and questions.

The 52100 steel in your knife was forged from a 5 ½ round bar, resulting in a reduction ratio by forging of over 95 points. The steel in your blade knew over 50 significant thermal cycles, was knowledgably forged to shape at low temperatures one hammer blow at a time, leaving enough steel to allow me to negate all sources of stress raisers and clean your blade to absolute premium steel. This blade is the best we can develop at this time.

When I started forging blades a number 7 grain was considered fine grain, a number 10 grain was considered the theoretical limit in 52100. We soon achieved the theoretical number ten grain and now have surpassed what was the theoretical limit and achieved a number 14 grain and finer in the lower third of the blade.

Your blade was differentially hardened three times at 24 hour intervals, then tempered three times again in three days. Twenty four hour cycles between hardening and tempering heats have proven to produce better blades. Each night the blade was placed in the freezer of my refrigerator. These hardening and tempering methods were carefully developed for our steel worked our way through many experimental blades tested to destruction.

The numerous thermal cycles and high degree of reduction by forging has produced a blade that manifests fine grain and a microstructure known as banding, one of the essential properties that made Wootz steel a legend in its time. Banding is a property of steel that knows high tensile strength and low resistance to compression, thus resulting in a blade that you can count on through tough use. Should you need to pry with the blade, it will be very strong and resistant to deforming, I doubt that you could bend it in your hands, and it will not break. In order to evaluate the lateral strength of our blades we use a torque wrench to measure the force applied. As an example the last blade we tested for lateral strength required a force of over 70 foot pounds to achieve the first 90 degree flex. It was a 5 inch blade measuring 3/16ths thick at the spine and ¾ of an inch from spine to cutting edge. The blade returned to within 15 degrees of straight on its own.

When I started making blades I sought to make the best knife possible, every year they have become better and the blades I make today are the best I can make hopefully we will continue to improve with each future knife. The geometry of your blade is fully convex; this results in a very strong blade. You will notice that the sides of the blade gain in volume toward the front third of the blade. I call this grind the Modified Michael Price Grind; I learned this profile from a blade stamped Michael Price, San Francisco. Not all blades that came from the shop of Michael Price were ground in this manner; I believe that those with this type of grind were made by Michael Price’s father. This blade profile allows me to dictate exactly where the blade will flex while maintaining strength in the front of the blade where it is needed.

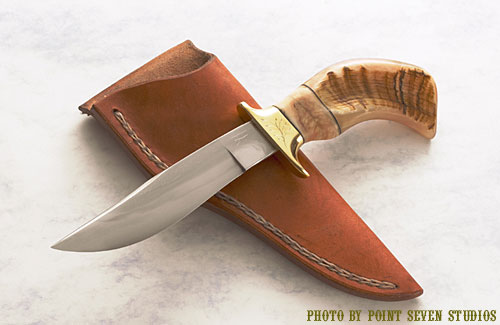

The sheep horn handles are a joy for me to work. The horn on these knives was harvested by me from a Ramboullet buck sheep, processed and aged for minimum 7 years to result in very stable handles. Each knife has its own character, a blend of artistry of nature and my abilities to bring pleasure to your hand and your eye.

Care of these knives is simple; the sheep horn in your handle has been carefully processed and aged in my drying sheds. The environment you live in will be different than mine; the sheep horn may shrink even more. All you need to do is apply a little natural oil to the handle, extra virgin olive oil or lanolin or Tree Wax or any natural wax that does not contain silicone is good enough. You can even use the natural oil many of us have behind our ears or on the side of your nose. Just rub your finger behind your ear and rub it on the handle. If you use the knife a lot the horn will absorb enough oil from your hands.

Any oil will keep rust from the blade, many times I simply apply the oil from the side of my nose or from behind my ear just like I suggested for the handle. Any brass polish will work on the guard. When the edge needs touching up, a few strokes on a smooth steel will bring the edge back to life. When you need to use a stone, I recommend a Norton Fine India stone. Again it will only take a few strokes to bring the edge back to an efficient cutting instrument.

In 2006 we confirmed through experimentation in my shop that we had achieved much of what we sought. Rex examined a blade in his laboratory and photomicrographs confirmed that we had achieved a milestone, what we call 52100 Wootz. The grain in your blade measures as ASTM 14 and finer supported by uniform banding. Banding is the property of steel that contributed to make Wootz blades the choice of those who sought greatness in their blades. Rex and I met in my shop to conduct the experiments, Tena Osborne filmed the event and our discussions about what and how we have achieved what we sought. From this point on all the knives I make will have the year they were made engraved on the blade along with my signature.

With the technical support of Jeremy Rivera we now have a DVD that explains what we have found. The information is as honest as we can make it and hopefully it will encourage future bladesmiths to continue the quest for Excalibur.

Etched Blades: In order to assure the quality of my heat treating process, all of my blades are etched in ferric chloride, revealing the true nature of the steel. You will see the effects of my differential, multiple quench hardening. The back of the blade is soft, and as you move from the back to the cutting edge, you can observe the transition zone as the steel becomes harder. You will see the ultra fine grain structure of the hardened steel along the bottom third of the blade.